Lithium-Ion Batteries

Lithium-Ion (Li-Ion or LIB)

Types:

- Lithium Iron Phosphate (“LFP”, LiFePO4)

- Lithium Iron Magnesium Phosphate (LiFeMgPO4)

- Lithium Manganese Oxide (“LMO”, LiMn2O4)

- Lithium Nickel Manganese Cobalt Oxide (“NMC”, LiNixMnyCozO2)

Lithium batteries have mostly been used where size and weight are important such as for small electronic devices, portable equipment, electric vehicles, and other mobile applications. More recently, the high cycle life of lithium has made it applicable with self-consumption grid-tied applications and the high current capability has made lithium a good choice for larger UPS systems. Due to the high cost of lithium batteries, they have not played a major role in stationary solar off-grid applications. However, this seems to be changing to some extent with the lowering costs and more lithium batteries becoming available.

Related Links:

- Custom Settings Info Pages for Battery Manufacturer/Models – Includes downloadable MSView Setup Wizard Files.

- Morningstar Best Practices by Battery Chemistry

- Energy Storage Partner Program

There are several advantages with Lithium batteries including the following:

- High Energy to Density and Weight Ratio for portable devices and electric vehicles

- High cycle lifetime used with grid-tied solar self-consumption usage with daily deep cycling

- High charge/discharge rate capability also known as charge acceptance is useful for quickly recharging cordless tools and EVs

- More stable and less variable voltage operating range which does not surge or dip with high charge/discharge rates. This can help with short-term grid-tied solar demand response

- Tolerant of remaining in a Partial State of Charge (PSoC) for long periods of time may help with some off-grid systems that have autonomy issues. Lithium batteries do not need to be fully charged regularly unlike most lead-acid batteries which can build up a sulfuric acid layer at the bottom of the battery cell known as stratification.

Possible disadvantages with lithium are as follows:

- Battery Management System (BMS) may be required for battery cell over-voltage/under-voltage and other protections

- Battery cell balancing may require more advanced BMS. Lead Acid batteries can be more tolerant of being overcharged with flooded batteries capable of periodic equalization charging.

- Coordination between battery BMS and other charging equipment and loads can add further complications

- Lithium batteries can be adversely affected by sustained periods with a very high SoC or very low SoC.

- Lithium batteries can be more susceptible to thermal runaway due to higher energy density.

- Charging lithium batteries while cell temperatures are below freezing may cause irreversible damage.

- Recycling and disposing of certain types of Lithium batteries may be more expensive due to toxicity.

- Lithium batteries are classified as dangerous goods and must be handled, packaged, labeled, and transported according to international regulations.

Requirements for using Morningstar Controllers typically include the following:

- Disable temperature compensation

- Disable Float stage

- Relays or MODBUS commands to switch off charging and/or loads to prevent high/low cell voltages or low/high cell temperatures. [Controlled eternally with advanced BMS that includes programmable logic control capabilities.]

- Fault Disconnect coordination possibly depends on the controller and Lithium battery BMS.

- Low temperature Foldback on the ProStar-MPPT controllers

- Please see Battery Management Systems (BMS) section (Link) for more information about integrating with BMS.

Morningstar controllers do not include a BMS for lithium batteries. The use of Morningstar controllers with lithium batteries is limited to the same type of voltage regulation limits that are provided for lead-acid batteries. Therefore, if there are imbalances between cells Morningstar controllers will not protect lithium batteries from cell over-voltages or under-voltages. Many lithium batteries include a BMS that can implement an internal battery disconnect. It is important that the battery will not implement an internal disconnect during charging. The best solution for preventing this is to use a BMS that can either disconnect the array input to the controller or disable charging with the controller by forcing a remote temperature sensor (RTS) disconnect. Another solution is to use conservative settings and monitoring of the battery cells to ensure that this will not occur. Damage to the controller due to a battery disconnect during charging is typically not covered under warranty. Incidental damage to loads due to voltage surges upon a battery disconnect is also not covered under warranty.

Morningstar recommends using caution when charging Lithium batteries with solar. Every Lithium battery is different. Even if it is made up of the same type of battery cells there can be differences between the BMS solutions which can make a significant difference in the behavior and performance of the battery. In addition to the Morningstar disclaimer regarding the information on this website below, it is the installer and ends user’s responsibility to eliminate the potential of any problems when designing, installing, and using lithium batteries with any Morningstar product.

Morningstar provides data logging for Morningstar products and some lithium batteries include data logging of the battery cells which is recommended as a best practice to detect potential problems with the system if external charge and load disabling is not possible with the BMS system.

ProStar MPPT and ProStar (Gen 3) Low Temperature Foldback

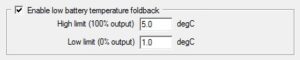

The ProStar MPPT and 3rd generation ProStar include Low-Temperature Foldback which can be used to protect lithium batteries from being charged in cold conditions. The custom settings temperature thresholds which define the bounds of charge current reduction due to low battery temperature can be programmed in MSView or with the Advanced Custom settings options with the display interface which is available with the built-in meter models of the ProStar MPPT (PS-MPPT-25M and PS-MPPT-40M).

The High Limit defines the lowest temperature at which the controller will deliver 100% of the controller’s rated output charging current. The Low Limit defines the temperature at which the controller will stop providing battery charging current. The charge current is tapered linearly from the High Limit to the Low Limit.

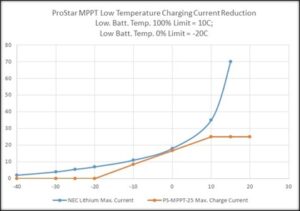

Example with NEC Energy Solutions ALM12V35 battery: High Limit 10C, Low Limit -20C, PSMPPT-25 (25A controller); at > 10C battery temperature controller will deliver 25A max charging current (if available); at -5C battery temperature it will deliver 12.5A max (if available); below -20C will deliver 0A.

The graph above displays the maximum charge current in blue for the NEC ALM-35 Lithium battery with a custom programmed Low-Temperature Foldback for the PS-MPPT-25 controller. This will allow the controller to continue to operate when the battery is exposed to low temperatures as measured with Morningstar’s remote temperature sensor (RTS) and allow it to recover the battery operation during low-temperature conditions. It should be noted that the RTS might not always be measuring the same temperature as the lowest cell temperature of the battery. This is where monitoring the lithium battery cell temperature can be considered in order to verify that there will not be a problem with the settings.

Disclaimer: Morningstar makes no representation, warranty, or assumption of liability regarding the information presented on this website regarding the various charging requirements for any type of battery or model. The material being presented is based on information that has been provided by other parties (such as battery specs and operational parameters) and uses assumptions that may or may not prove to be valid or up to date.