Click here to download and view the PDF Version.

Parallel Charging Using Multiple Controllers With Separate PV Arrays

Large off-grid and battery backup PV systems, often require greater charging than a single controller can provide. To meet the charging requirements of these large systems, several TriStar™ or TriStar MPPT™ controllers can be connected in parallel to a battery bank. Each controller is connected to its own separate PV array. This document provides answers to frequently asked questions, and tips concerning the operation and setup of these large multiple TriStar and TriStar MPPT controller systems.

March 11, 2015

Introduction:

Morningstar manufactures solar controllers for charging battery banks with nominal voltages of 12 to 48 Vdc and a range of maximum charging currents from 4 to 60 Amps. The TriStar and TriStar MPPT controllers have the highest charging current ratings with 30A, 45A or 60A maximum charging. Larger battery banks often require greater charging than a single controller can provide. Generally, there is no problem with charging battery banks with several charging sources. The TriStar MPPT manual states the following. “Multiple TriStars can be installed in parallel on the same battery bank to achieve higher charging current. Additional parallel controllers can also be added in the future.” Here are a few considerations for the use of parallel solar controllers:

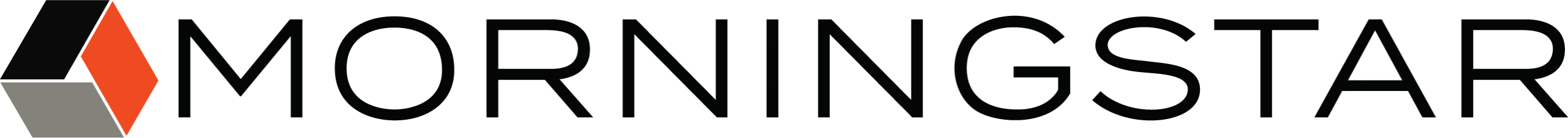

- Each solar controller must have its own separate solar array and each array is configured and sized in accordance with the solar controller specifications.

- The batteries need to be designed to handle the combined charging currents. Contact the battery manufacturer if there is any question as to recommended max. charging current.

- The charging sources and controllers are set up properly (explained below).

Basic Wiring Diagram for 2 TriStar MPPT controllers in parallel

Solar controllers are often used with other 3rd party charging sources. Often these other charging sources may be generators or AC chargers used for backup charging. For instance, a generator may be activated to provide bulk charging when the battery voltage is getting low, leaving the regulation charging to the solar PV controller. With Grid-Tied battery based Inverter/chargers, the inverter can be set at a lower “sell back” voltage than the controllers’ regulation voltage. This allows the controllers to continue operating at full bulk charging power while the inverter/charger is in “sell” mode. Such scenarios present no conflict between the different charging sources.

Morningstar’s TriStar and TriStar MPPT controllers have been designed to coordinate parallel charging control effectively without the need for intercommunication between products. While it is always possible to have one controller handle most of the charging regulation alone, as in cases when using 3rd party charging sources, the TriStar and TriStar MPPT controllers’ voltage regulation is accurate enough to synchronize and coordinate the charging regulation for parallel operation.

Key Factors of Parallel Setup:

Since Morningstar uses voltage based State of Charge (SOC) for voltage regulation, no direct communication between the controllers is necessary to ensure they charge correctly in tandem. The controllers will transition to and from the different charging states at approximately the same time if all of the following conditions exist:

- All of the controllers are set with the same charging profile

- Use the same DIP Switch settings for matching the charging control.

- If creating a custom setup in MSView, save the custom setup configuration by using “Write to File” in the Setup Wizard to program all of the controllers with the same settings.

- There is a connection from the battery bank to each controller’s Voltage Sense Terminal pair. This ensures each controller is measuring the same battery bank voltage. Note: paralleling between controllers’ Voltage Sense terminals, in order to share a single connection to the battery bank is an acceptable practice.

- A battery Remote Temperature Sensor (RTS) is used with every controller. This ensures all controllers will be measuring the same temperature for regulation charging, voltage temperature compensation. If the batteries are located indoors in a climate controlled area it may be acceptable to omit an RTS. Note: An RTS is included in the TriStar MPPT box, but not with the TriStar. If using TriStar controllers, RTS’s must be purchased separately for each controller. A single RTS CANNOT be paralleled or shared between multiple controllers.

During absorption (or boost) charging, the parallel controllers will start limiting the voltage at approximately the same time, since they will all be sensing the same voltage and have the same charging profile. The RTS and voltage sense connections help to achieve this charging synchronicity.

The controllers may end absorption charging at slightly different times, but this will typically be of little or no consequence to the health of the batteries. Usually the lagging controller will continue to hold the voltage in regulation and complete the cycle shortly after the other controller(s) have already transitioned to float. In larger systems, a lagging controller may not apply enough charging current to offset the loads to maintain absorption voltage. Often the voltage will eventually decrease to the float voltage, so the float voltage stage is still in effect.

If a lagging controller is causing the voltage to stay higher than float, but not high enough to complete absorption charging, this does not necessarily indicate that there is a problem. At the end of an absorption charging state, it should not take much current to maintain absorption regulation voltage, so it may indicate that the batteries are not fully charged and additional charging may be needed for the given day.

Voltage intolerances can also cause one or more of the controllers to start and finish the absorption charging stage earlier than other controllers in the system. This should have no noticeable effect on battery health. However, if there is a concern about this, custom programming provides the ability to make small adjustments to the regulation voltages and timing to get the controllers to more closely match each other.

Since Morningstar’s voltage regulation is very accurate and there is a voltage sense connection to each controller (there are no voltage drops that might cause each controller to read different voltages) this setup as proven to be effective. Product polling over a communications bus has not been found to be necessary making it simpler to install. The controllers act autonomously without any concern with setting up a communications link.

If the batteries will be equalized, it is important that all parallel controllers equalize at the same time. The TriStar MPPT manual states that “if two or more TriStar MPPT controllers are charging in parallel, each controller may attempt to equalize on a different day. Systems with multiple controllers should only equalize manually to ensure synchronization between controllers.” If automatic equalize (DIP switch 7) is ON, the equalization schedule between the controllers may not be synched. This could cause multiple days of equalization unintentionally and may cause a high voltage disconnect (HVD) alarm for the controllers not equalizing on the given day. It is recommended that DIP 7 be set to OFF for manual equalization. Typically, flooded batteries need regular maintenance and the manual equalization can be part of the scheduled maintenance for the system.

Related Accessories:

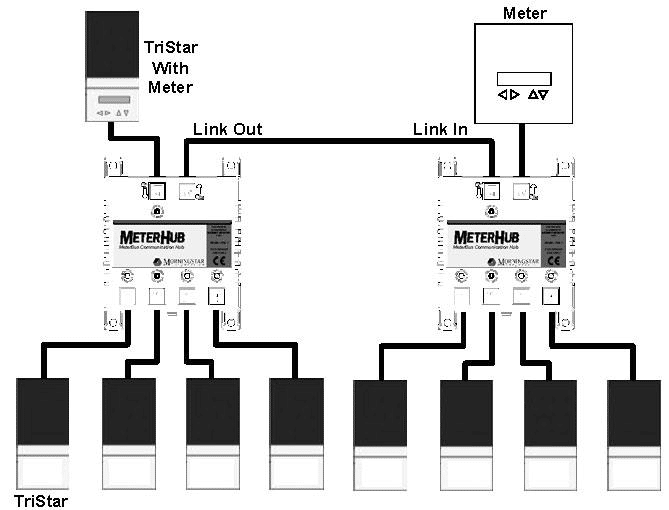

MeterHub™:

The MeterHub was designed specifically for systems with multiple controllers. In addition to displaying information from any individual controller or aggregated system totals, it allows simultaneous initiation of an equalization charging cycle for all TriStar or TriStar MPPT solar charge controllers in the system. The equalization is activated by a TriStar Meter 2. Manual equalizing like this is the best way to make sure that equalization starts at the same time for all of the controllers.

TriStar Meters (TS-M-2, TS-RM-2 and TS-M-2-600V):

A TriStar meter can be installed on each individual TriStar or TriStar MPPT controller, or with the MeterHub, a single TriStar meter can be shared between all controllers. A TriStar meter connected to a MeterBus network will display information for each individual controller and the aggregate system data (total Amps, Watts, Ahs etc.) of all units together.

Communications:

There are several options for setting up a local or remote PC connection for real-time data display, customizable data logging, or downloading internally logged data. In addition to Ethernet and/or serial port configurations, a TriStar MPPT (TS-MPPT-60 or TS-MPPT 600V) can be configured as an Ethernet to EIA-485 Bridge to other TriStar MPPT or TriStar units in the system. Please note that the MeterBus network and MODBUS (PC) Network are separate networks and do not share data. See related documentation on communications, product manuals and MSView software available on the Morningstar Support Site.